Northwestern Water and Sewer District – Perrysburg Sewer System I/I Reduction

Learn how NWWSD partnered with Jones & Henry on a project to reduce excessive infiltration/inflow (I/) in the Perrysburg sewer system.

Posted on: July 9, 2018

Jones & Henry has worked with the Wood County, Ohio-based Northwestern Water & Sewer District (NWWSD) on several key projects for this regional water and sewer district throughout the past few years – including the SS-200 Flow Equalization Improvements project, which received an American Council of Engineering Consultants (ACEC) Honor Award this winter.

So, when it came time to find a partner for a new project to reduce excessive infiltration/inflow (I/) in the Perrysburg sewer system, NWWSD didn’t hesitate to choose to work with their trusted partner for water engineering: Jones & Henry.

Solutions

This project included the rehabilitation of over 44,000 feet of 8-inch through 42-inch separated sanitary sewers using mainline grouting, point repairs, and sectional cured-in-place pipe (CIPP) liners.

Also, closed-circuit television inspection reports for the pre-construct inspection were made available to bidders via an online file transfer protocol during the process.

Through a detailed analysis of the closed-circuit television reports, Jones & Henry and the District decided to select a test and grout method to address joint defects for the majority of the sewer mains in this collection system. The use of sewer grouting permitted the District to realize significant cost savings versus other rehabilitation methods on this project.

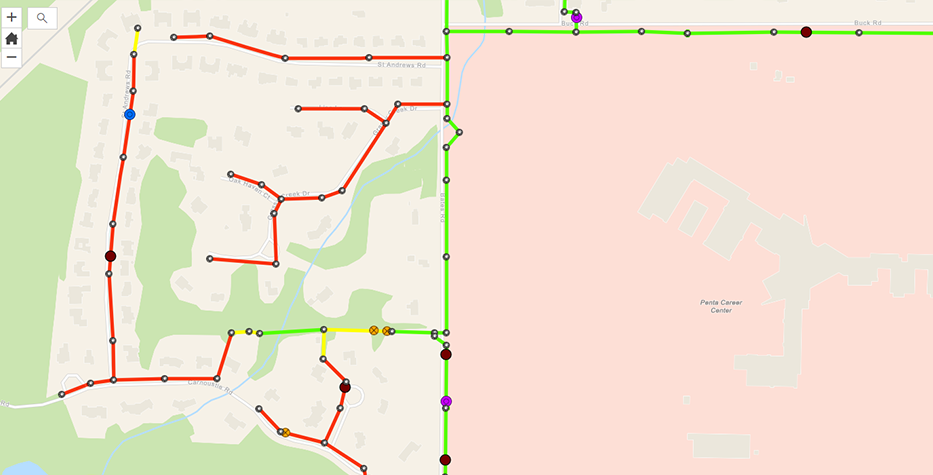

In addition, a defect map was also developed to show the required repairs in each sewer reach using a GIS web application provided to bidders.

The “Paperless Project” Concept: New Project Delivery Method

But perhaps what is most notable about this project was that it was completed using Jones & Henry’s new “Paperless Project” concept for project delivery. This new method allows projects to be managed almost entirely without printed documents served through an online presence, resulting in minimal to nearly no printed paperwork.

Everyone involved in this project – including Jones & Henry, the bidder/contractor, and NWWSD – benefited from this revolutionary new project delivery method because of the improved project accuracy, reduced costs, and increased volume of data it provided.

Results

Besides reaping the benefits offered by the “Paperless Project” project delivery method, the Perrysburg sewer system has been able to reduce a significant amount of clean water I/I.

Related Articles

Village of North Baltimore ...

July 20, 2018

Battle Creek Solids Handlin...

February 15, 2018

Lima, Ohio – Wastewat...

February 15, 2018

Oregon Road Altitude Valve ...

November 3, 2023