In recent years, many communities have faced significant challenges in maintaining safe and high-quality drinking water. The Village of Archbold, with its 7.6 million gallons per day (mgd) surface water treatment plant, was no exception. Identifying issues related to trihalomethanes (THMs) and coping with an aging infrastructure prompted the Village to take decisive action. Enter Jones & Henry, a trusted partner who developed a comprehensive plan to address these challenges and improve the overall water quality for Archbold and its surrounding communities.

The Beginning of a Transformation

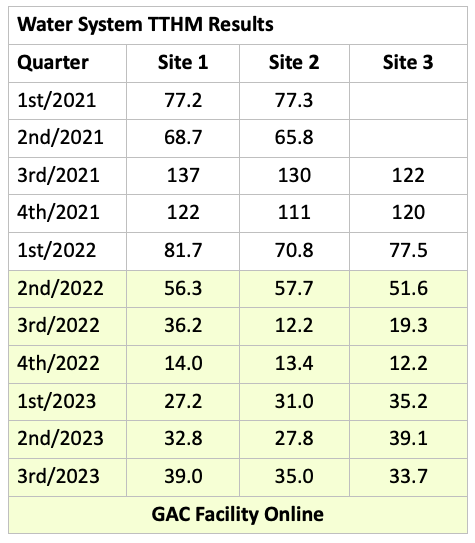

The transformation journey began with a thorough evaluation of the existing water treatment plant. That included a detailed assessment of processes, equipment, and filter media, laying the groundwork for targeted improvements. With the aim of reducing THMs—harmful byproducts formed when chlorine disinfectants react with organic matter—Jones & Henry conducted a granular activated carbon (GAC) pilot study. This study was crucial in determining the most effective GAC media to lower total organic carbon (TOC) levels, which directly impact THM formation.

Collaboration was key throughout the process. Working closely with the Village and the Ohio Environmental Protection Agency (EPA), Jones & Henry developed a pilot protocol and a General Plan for comprehensive water treatment improvements. This collaborative effort ensured that all plans adhered to regulatory standards and addressed the Village’s specific needs.

Major Upgrades and Innovations

After careful planning, construction on the upgrades commenced, with completion in June 2022. The project included transformative changes such as:

- Transitioning from a gaseous chlorine system to a safer sodium hypochlorite system.

- Replacing existing gravity filter media and incorporating an air scour system to enhance filter efficiency.

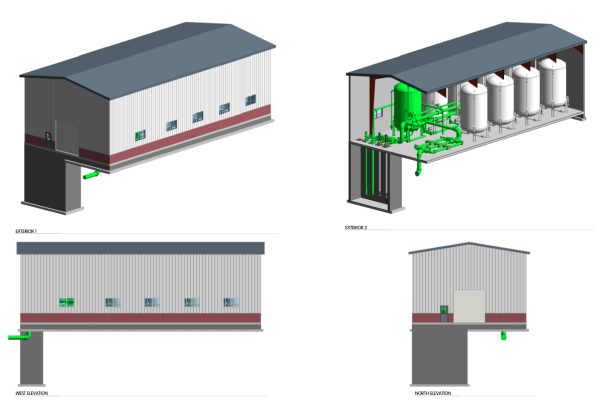

- Installing a new GAC and ultraviolet (UV) disinfection facility.

- Adding mixers to two existing clearwells and improving chemical feed systems.

- Implementing SCADA upgrades for better operational control and monitoring.

Jones & Henry was pivotal throughout the entire design phase, managing process, site, architectural, structural, mechanical, electrical, and controls design to ensure seamless integration of the new systems.

Achieving Compliance and Improving Quality

The results of these extensive upgrades were immediate and impressive. Within three months of the new GAC facility coming online, Archbold was in full compliance with TTHM regulations. The annual average THM levels at all test sites fell below the critical threshold of 80 micrograms per liter (ug/L), significantly enhancing the health and safety of the drinking water supply.

Ongoing Support and Optimization

The commitment to water quality doesn’t end with project completion. Jones & Henry Engineers continues to play a vital role in monitoring water quality results. By helping the Village optimize the life of the GAC media, they’ve implemented a plan that significantly extends the time before regeneration is necessary. That not only enhances water quality but also provides economic benefits by saving costs associated with media change-outs.

Conclusion

The transformation of the Village of Archbold’s water treatment plant is a testament to the power of collaboration and strategic planning in overcoming environmental challenges. With the dedicated support of Jones & Henry, Archbold is not only meeting regulatory standards but is also paving the way for a sustainable future. As we reflect on this project, it serves as a poignant reminder of the importance of investing in infrastructure and technology to safeguard our most vital resource: clean drinking water.

For communities facing similar challenges, the success story of Archbold may serve as an inspiration to explore innovative solutions that ensure the health and safety of their water supply for years to come.