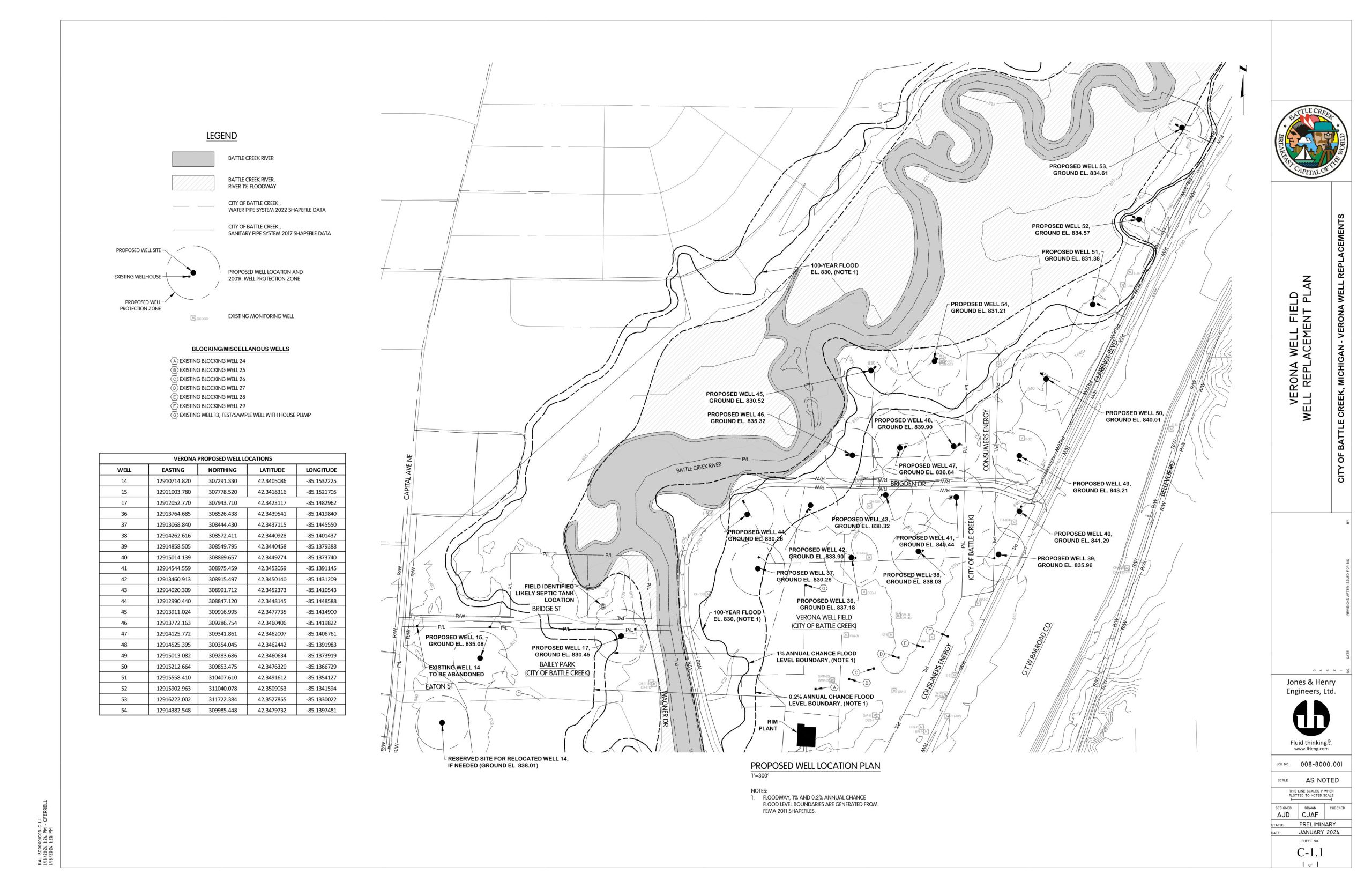

The City of Battle Creek pumps 100% of its drinking water from the Verona Wellfield in the Northeast corner of the City. This wellfield has been the City’s primary water supply for over a century and has a daily permitted pumping capacity of over 39 million gallons.

Battle Creek’s wellfield is particularly susceptible to contamination due to an adjacent Superfund Site. Working off a hunch/intuition the City televised their wells and found significant defects in the well casings which were allowing water from the glacial drift aquifer into wells that were supposed to be drawing from the confined Marshall Sandstone Aquifer. Working with the City, J&H alerted the State who followed the required regulatory path by issuing an Administrative Consent Order (ACO).

To comply with the ACO, the City worked with Jones & Henry to begin the process of applying for approval to drill test wells to replace all their current production wells. J&H assembled a team of experts including Jim Brode of Fleis & Vandenbrink Engineering due to his extensive past work with the Verona Wellfield, under prior employment. The Superfund Site also maintains a groundwater consultant as part of their responsibilities under a court order and a US EPA Consent Decree. This large group of interested parties began a year-long process to perform the necessary hydrogeological study and produce the necessary documentation to allow EGLE to approve the drilling of the test wells. Biweekly team meetings were held virtually to ensure all concerns were addressed in a timely fashion and that there was full transparency amongst all the stakeholders. This project is the largest wellfield rehabilitation project in the history of the State of Michigan.

Throughout design, J&H worked with all the project stakeholders to walk them through the design aspects and approval process. J&H staked well sites and produced detailed maps for stakeholder review and comments. J&H produced documents for State submittal and approval. Project work includes drilling of 22, 16-inch diameter test wells, aquifer testing, and conversion to production drinking water wells. In some instances, existing pumping equipment will be relocated to the new offset wells to maintain appropriate costs. For those wells where equipment is outdated or in need of extensive services, new well pumping equipment was designed for installation. J&H is designing two separate construction projects at the wellfield to be constructed concurrently, so it was extremely important to manage the various scopes to ensure there are no gaps.

The project has been bid and awarded at a cost of $7,601,965.93. Design engineering has cost was $370,000. Drilling of the test wells is expected to commence in July of 2024.